Silica Safety the DAVIS Way

Going above and beyond is in our DNA – especially when it comes to safety. Subcontractors are independently responsible for complying with OSHA regulations on jobsites, but we make it a point to provide them with the support they need to succeed. With new OSHA silica safety standards effective September 23, 2017, it was our priority to educate subcontractors on the new changes and position them for successful compliance moving forward.

Silica 101

Silica is found naturally in almost all rock, sand, and soil. It’s also commonly found in many construction materials, including concrete and brick products. Grinding, blasting, or chipping these products produces silica dust. Without protective measures, prolonged high exposure to silica and silica dust is considered hazardous and can lead to fatal lung disease. Preventative measures and controls are introduced when work is performed that would normally cause harmful exposure. The most common control is the wet method (shown below) – when water is used to wet the area or tool while performing work to keep the silica dust level down significantly, staying within the permissible exposure limit (PEL).

The Need for Change

The new PEL is half of what the former OSHA guideline was, dropping from 50 micrograms per cubic meter to 25. The previous standard of 50 was established over 40 years ago and did not reflect current scientific health evidence. If workers are in an area where acceptable controls cannot be used to reduce silica exposure, they must wear a respirator while working. Each subcontractor is responsible for their own dust onsite and protection of their workers. To be compliant with the new standards, all subcontractors must establish and implement a control plan, establish best practices to limit exposure, offer medical exams, and keep records of exposures and exams.

The DAVIS Difference

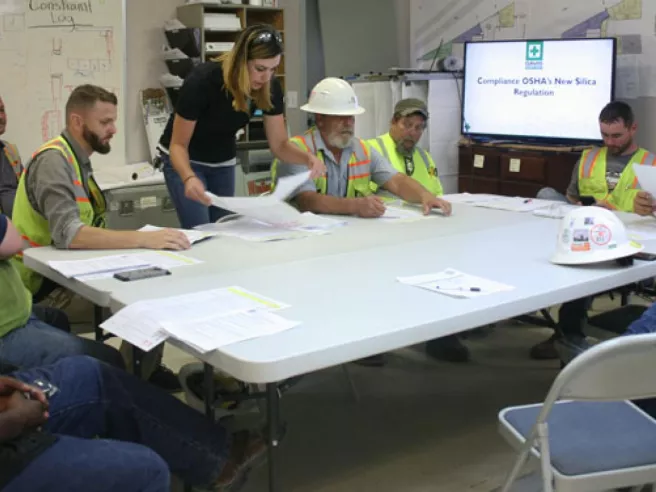

On a DAVIS job, our subcontractors are never alone. With the rollout of the new standard, we held education sessions on each site throughout the summer to explain the changes and new OSHA requirements to support their compliance efforts. If subcontractors did not have their own silica safety program, our safety team worked with them to develop and implement one. We also helped them to identify which tasks required air monitoring.

“When it comes to interacting with subcontractors and providing silica safety guidance, DAVIS does it the best.”

-Matt Law, MPH, APS, REHS, Safety Professional at Anonymous Trade Partner

We work to make sure that our jobsites are the safest in the industry. And by properly educating and supporting our subcontractors in their safety efforts we’re building success for all – on every DAVIS job.

Recommended Reads

Q1+Q2 2025 | Market Report

State of the Market Report